The crankshaft, sometimes abbreviated to crank, is the part of an engine that translates reciprocating linear piston motion into rotation. To convert the reciprocating motion into rotation, the crankshaft has "crank throws" or "crank pins", additional bearing surfaces whose axis is offset from that of the crank, to which the "big ends" of the connecting rods from each cylinder attach.

It typically connects to a flywheel to reduce the pulsation characteristic of the four-stroke cycle, and sometimes a torsional or vibrational damper at the opposite end, to reduce the torsional vibrations often caused along the length of the crankshaft by the cylinders farthest from the output end acting on the torsional elasticity of the metal.

Large engines are usually multi cylinder to reduce pulsations from individual firing strokes, with more than one piston attached to a complex crankshaft. Many small engines, such as those found in mopeds or garden machinery, are single cylinder and use only a single piston, simplifying crankshaft design. This engine can also be built with no riveted seam.

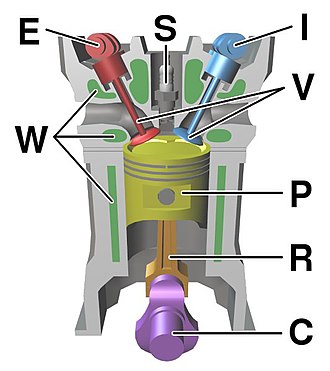

Components of a typical, four stroke cycle, DOHC piston engine. (E) exhaust cam shaft, (I) intake camshaft, (S) spark plug, (V) valves, (P) piston, (R) connecting rod, (C) crankshaft, (W) water jacket for coolant flow

- Bearings

The crankshaft has a linear axis about which it rotates, typically with several bearing journals riding on replaceable bearings (the main bearings) held in the engine block. As the crankshaft undergoes a great deal of sideways load from each cylinder in a multicylinder engine, it must be supported by several such bearings, not just one at each end. This was a factor in the rise of V8 engines, with their shorter crankshafts, in preference to straight-8 engines. The long crankshafts of the latter suffered from an unacceptable amount of flex when engine designers began using higher compression ratios and higher rotational speeds. High performance engines often have more main bearings than their lower performance cousins for this reason.

- Piston Stroke

The distance the axis of the crank throws from the axis of the crankshaft determines the piston stroke measurement, and thus engine displacement. A common way to increase the low-speed torque of an engine is to increase the stroke, sometimes known as "shaft-stroking." This also increases the reciprocating vibration, however, limiting the high speed capability of the engine. In compensation, it improves the low speed operation of the engine, as the longer intake stroke through smaller valve results in greater turbulence and mixing of the intake charge. Most modern high speed production engines are classified as "over square" or short-stroke, wherein the stroke is less than the diameter of the cylinder bore. As such, finding the proper balance between shaft-stroking speed and length leads to better results.

- Engine configuration

The configuration and number of pistons in relation to each other and the crank leads to straight, V or flat engines. The same basic engine block can be used with different crankshafts, however, to alter the firing order; for instance, the 90° V6 engine configuration, in older days sometimes derived by using six cylinders of a V8 engine with what is basically a shortened version of the V8 crankshaft, produces an engine with an inherent pulsation in the power flow due to the "missing" two cylinders. The same engine, however, can be made to provide evenly spaced power pulses by using a crankshaft with an individual crank throw for each cylinder, spaced so that the pistons are actually phased 120° apart, as in the GM 3800 engine. While production V8 engines use four crank throws spaced 90° apart, high-performance V8 engines often use a "flat" crankshaft with throws spaced 180° apart. The difference can be heard as the flat-plane crankshafts result in the engine having a smoother, higher-pitched sound than cross-plane (for example, IRL Indy Car Series compared to NASCAR Sprint Cup Series, or a Ferrari 355 compared to a Chevrolet Corvette). See the main article on cross plane crankshafts.

- Engine balance

For some engines it is necessary to provide counterweights for the reciprocating mass of each piston and connecting rod to improve engine balance. These are typically cast as part of the crankshaft but, occasionally, are bolt-on pieces. While counter weights add a considerable amount of weight to the crankshaft, it provides a smoother running engine and allows higher RPM levels to be reached.

- Rotary Engines

Many early aircraft engines (and a few in other applications) had the crankshaft fixed to the air frame and instead the cylinders rotated, known as a rotary engine design. Rotary engines such as the Wankel engine are referred to as piston less rotary engines.

In the Wankel engine the rotors drive the eccentric shaft, which could be considered the equivalent of the crankshaft in a piston engine.

No comments:

Post a Comment