INTRODUCTION

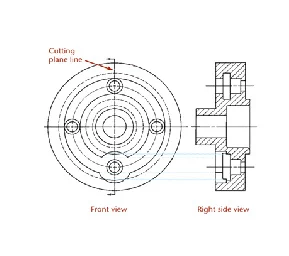

In engineering drawing, various objects have invisible or hidden interior features, which are represented by dotted lines in their projection views. But, when the features, are too many, the orthographic projections obtained get complicated and difficult to understand. In order to understand the interior view details, the object is cut an imaginary cutting plane called Sectional Plane. The part of the object between the cutting plane and the observer is assumed to be removed and view is then shown in section. The view thus obtained is called Sectional View.

Sectional View

The view obtained by cutting an object with an imaginary cutting plane is called Sectional View.

The surface produced by cutting the object by the section plane is called Section. It is indicated by thin section lines uniformly spaced, generally at an angle of 45'. As already imagined, a sectional view is a view seen when a portion of the object nearest to the observer is imagined to be removed by means of a cutting plane or planes, thus revealing the interior construction. The other views are not affected in any way always represent the entire object.

Types Of Sectional Views

The sectional views are of mainly two types. These are dependent upon the number of cutting planes cutting the object.

- Full Sectional View.

- Half Sectional View.

Full Sectional View

The view obtained after removing the front half portion of an object is called a Full Sectional Views or Front Sectional Views or Simply Sectional Elevation.

When the cutting plane cuts the object lengthwise, full sectional front view is obtained. It is also called longitudinal section. It may be noted that the top view or the slide remain unaffected, that means top view is drawn full not half.

The Cutting Plane

- The cutting plane is shown in a view adjacent to the sectional view.

- In the section view, the areas that would have been in actual contact with the cutting plane are show with section lining.

Lines

Behind the Cutting Plane

- The visible edges of

the object behind the cutting plane are generally shown because they are now

visible but they are not cross-hatched.

The

Cutting Plane

Placement

of Section Views

- Section views can

replace the normal top, front, side, or other standard orthographic view.

Placement

of Section Views

Labeling

Cutting Planes

- When more than one

cutting plane is used, it is especially important to label them for clarity.

Line

Precedence

- When a cutting plane

coincides with a center line, the cutting plane line takes precedence.

- When a cutting plane

line would obscure important details, just the ends of the line outside the

view and the arrows can be shown.

Rules

for Lines

- Show edges and

contours which are now visible behind the cutting plane.

- Omit hidden lines in

section views.

- A section-lined area

is always completely bounded by a visible outline.

- The section lines in

all hatched areas for that object must be parallel.

- Visible lines never

cross section lined areas.

Section

Line Mistakes

Cutting

Plane Line Style

- Cutting lines are

thick lines (0.7 mm).

- The preferred cutting

plane line style is made up of equal dashes ending in arrowheads.

Section

Line Technique

- Uniformly spaced by

an interval of about .10”

- Uniformly thin, not

varying thickness

- Do not run beyond

outer edges of the visible lines

- Usually at 45˚ angle

Section

Line Mistakes

Section

Line Technique

Section

Lining Symbols

Half

Sections

The view obtained after removing the front quarter i.e. one fourth portion of an object by means of two cutting planes at right angle to each other is called Half Sectional View or Half Sectional Elevation.

It may be observed that the plane or top view also remain unaffected i.e. full side view is drawn.